|

Projects Publications Resume Contact About Youtube |

|

I picked up a Flsun V400 3D printer from my local Micro Center after my DERP 3550 broke for a third time.

Assembly was quick and easy. It worked great for me right away. Initial prints were surprisingly fast and surprisingly high quality. Some cost-cutting measures are apparent, but it seems like a decent value overall and it seems like a very capable printer. I can't speak to longevity or reliability yet, but I'm hopeful.

If this printer were available sooner, I likely wouldn't have gone down the custom printer path. And now that I have a working V400 and a broken DERP 3550, I'm trying to figure out if DERP repairs and upgrades are worth my time and energy.

Note that print speed and quality are not in my list of initial gripes.

The hotend heat block and nozzle are not quite square to the effector plate. It's printing fine, but something must have bent slightly during assembly and made it past QC. I'll eventually disassemble it to see what's going on, but I'll likely wait until something breaks or I notice a print quality issue.

The filament runout sensor is fiddly. There is too much unconstrained room between the housing and the micro switch. It's not a big deal, but it can take a few tries to get the filament though.

I'm just not a Cura fan. I got a couple usable prints with it and the provided profiles, but I don't like the way it slices some things and I experienced some nozzle dragging. After some searching, I saw lots of workarounds for the nozzle dragging. I've also had that same dragging issue with the default Prusa i3 MK3S profile. Cura also seems to treat some CAD union objects exported to STL as zero-gap separate objects when slicing. So I prefer PrusaSlicer because I'm more familiar, I haven't seen any nozzle dragging, and STL objects are sliced the way I expect.

Some searching led me to two starting points:

Many thanks to these folks for posting. These are a great starting point, and very much appreciated, but not quite what I was looking for. I'd really like to see the printer, filament, and print oriented configuration that PrusaSlicer is designed around. I don't like to print flat out or slow silent all the time. I'd like a variety of print profiles. Different filaments have different volumetric flow rates and retraction requirements, so a variety of filament profiles for the V400 hotend and extruder would be nice too.

Work is still in progress, but here is my starting point. The flsun_v400_prusaslicer_20230418.zip contains 3 .ini files, which can be dropped into the PrusaSlider configuration printer, print, and filament directories. This is very slow by default and I've been manually tweaking speeds and accelerations for testing. It will be a good amount of work to come up with a good set of profiles.

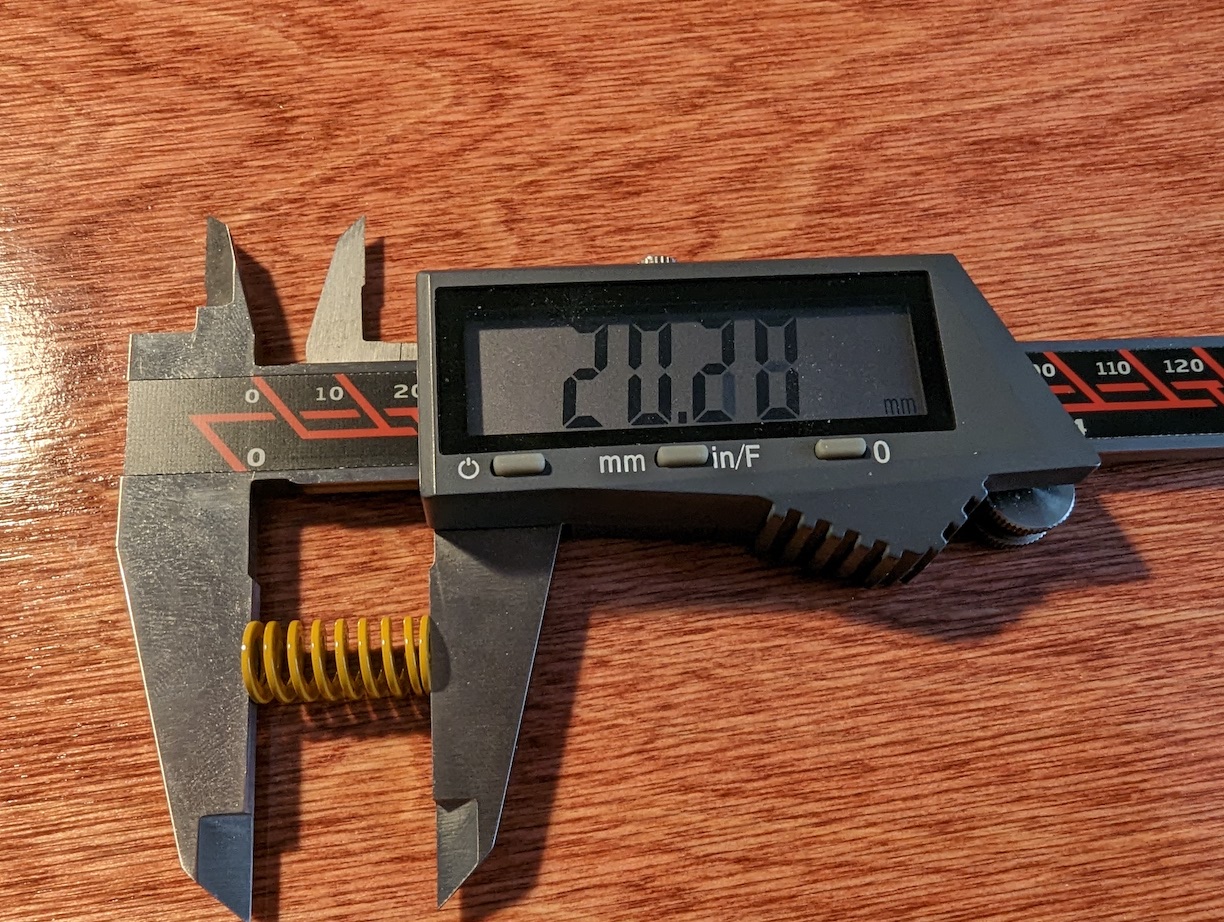

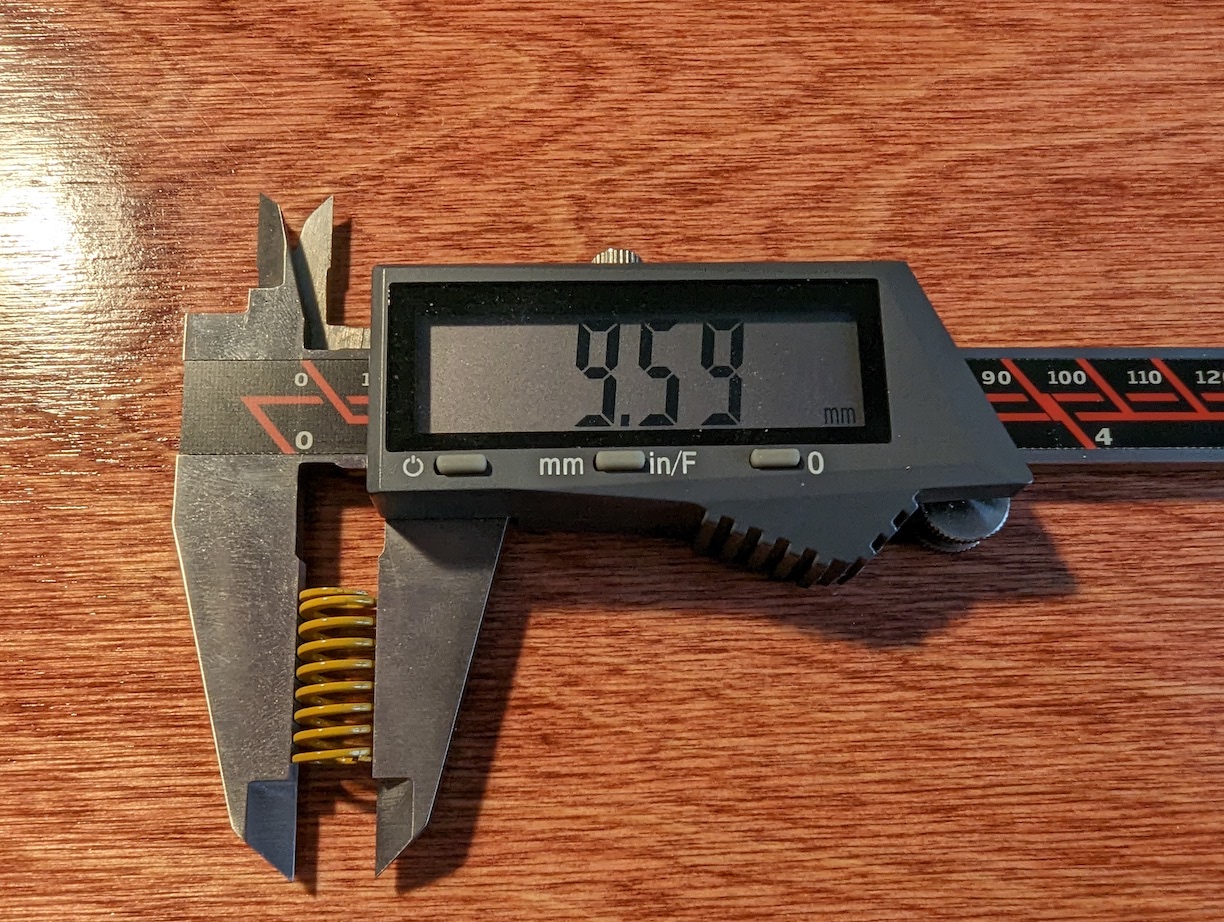

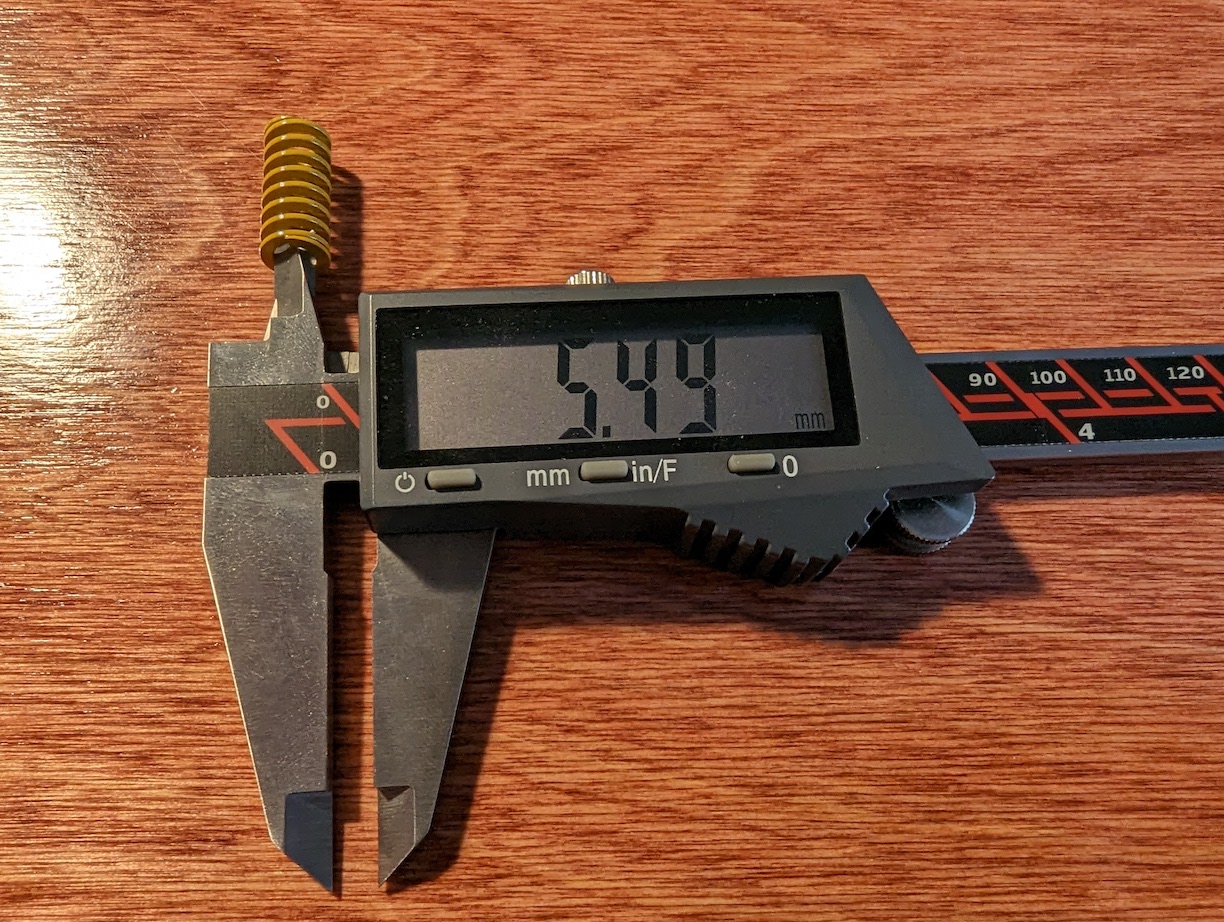

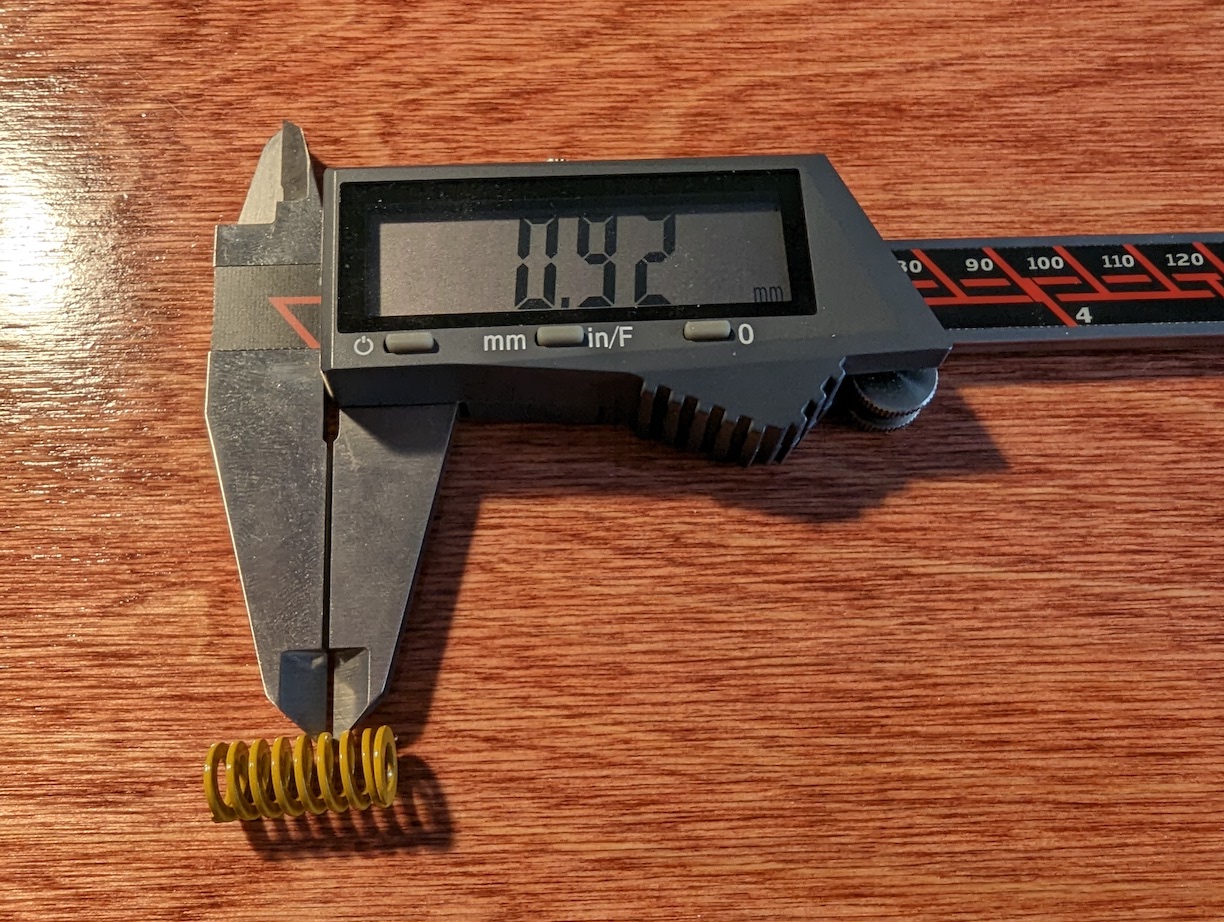

I really like the belt tensioner mechanism. It's designed for constant set tension and it's designed to prevent over-tension. The description in the instructions is pretty difficult to understand, but it makes sense as soon as you turn it around and see it. With the idler block loose and the tensioner block fixed, tightening the knob pulls on the idler and puts more tension on the spring. When the knob bottoms out on the tensioner block, spring pressure cannot be increased any futher and belt tension is set. Then the idler can be tightened to prevent movement.

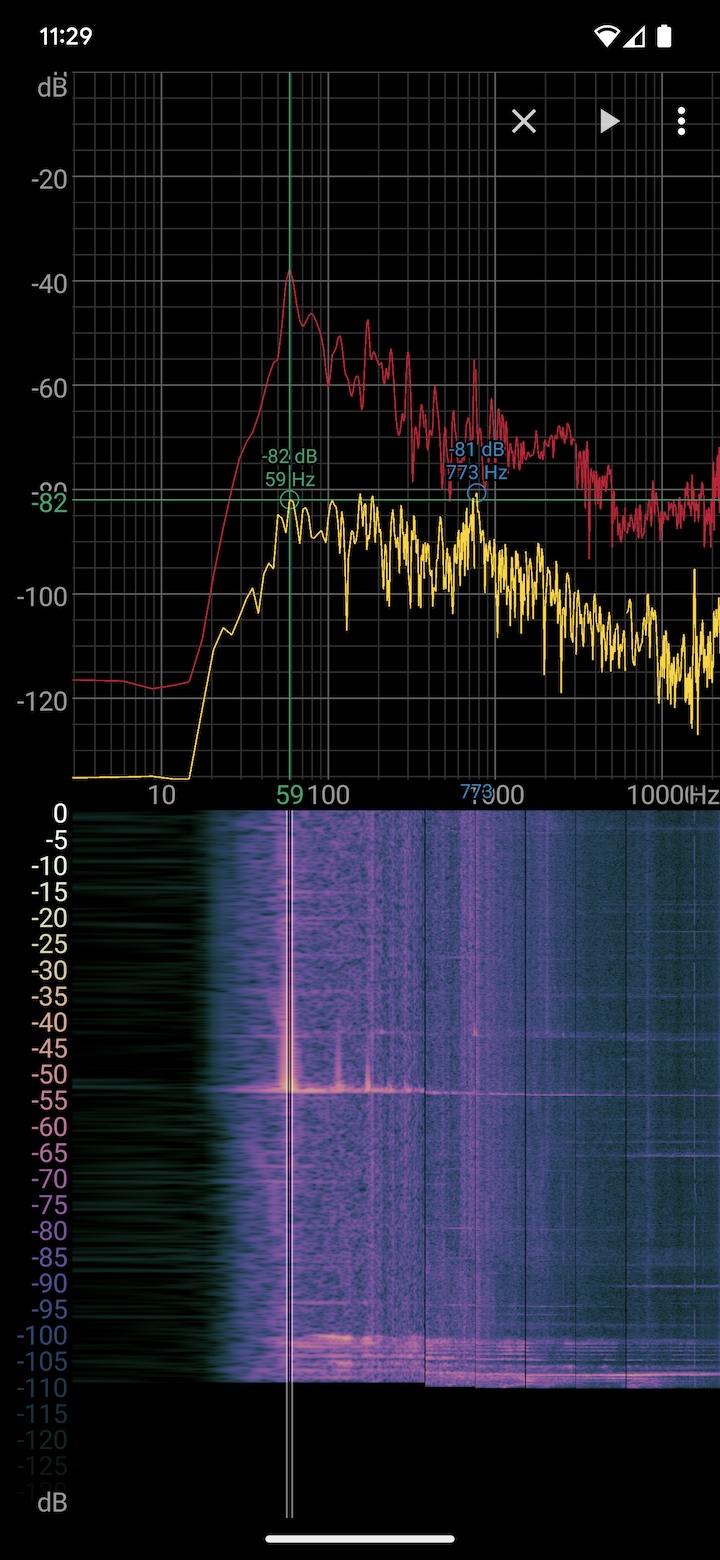

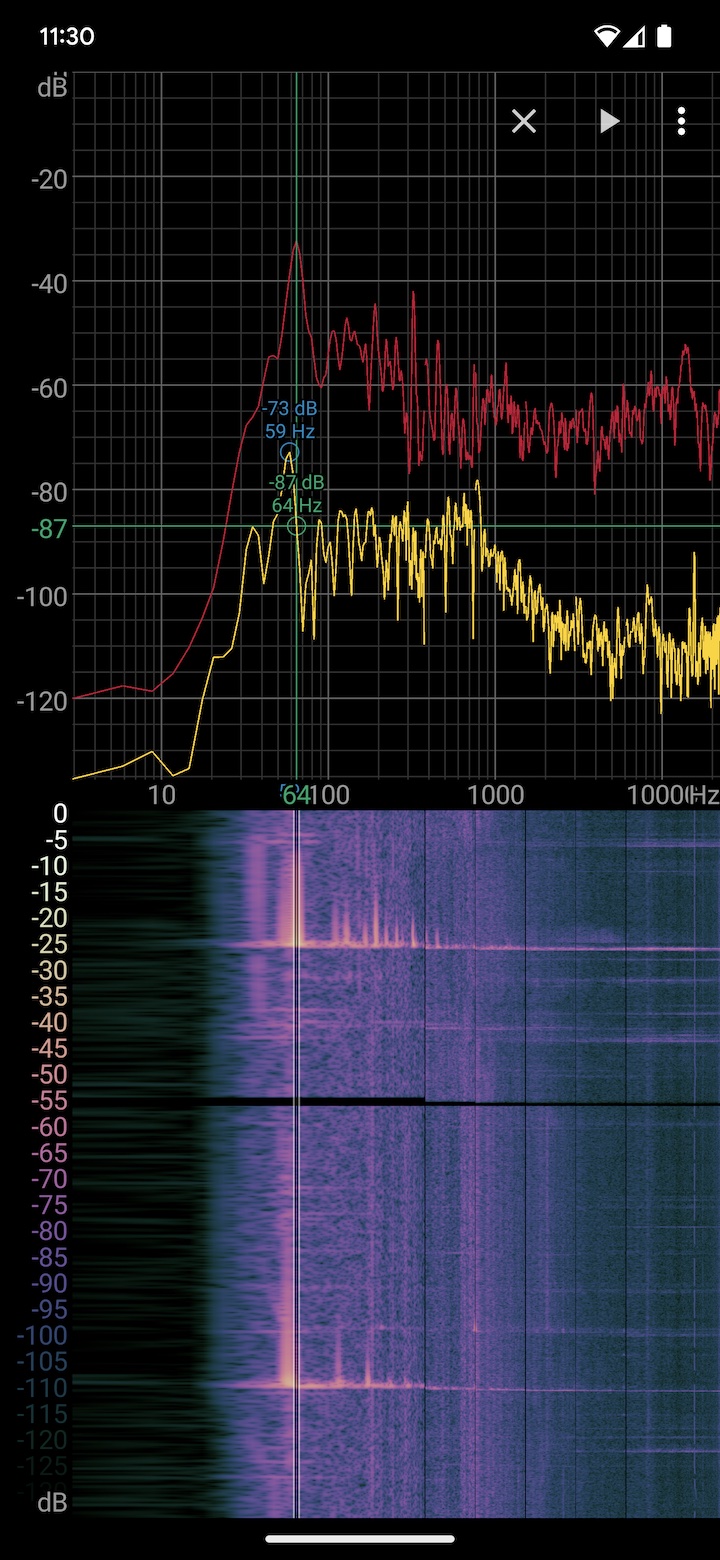

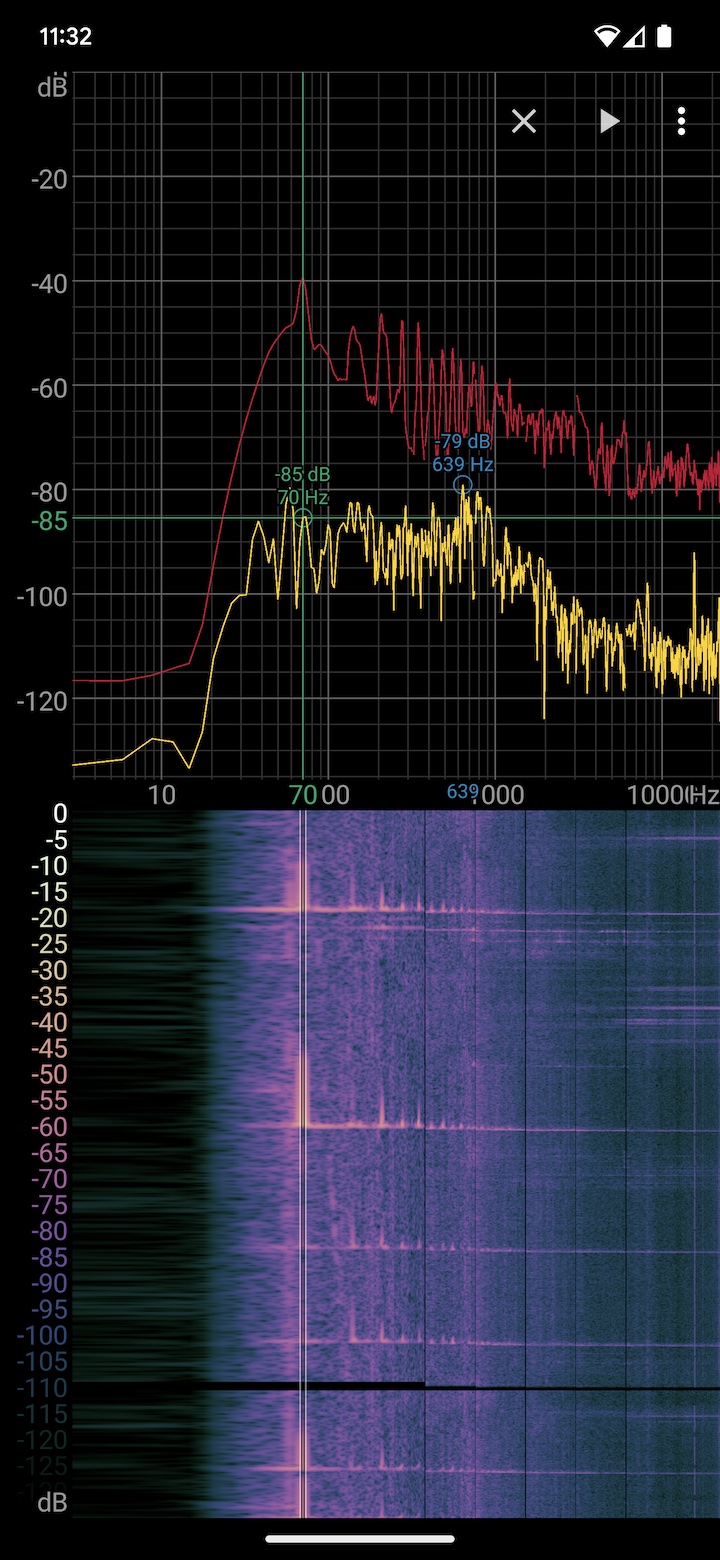

I used the Android Spectroid app to measure the freshly-tensioned belt frequencies over multiple plucks. They were fairly close at 59Hz, 64Hz, and 70Hz. They could be fine tuned by loosening the high frequencies or washer shimming the spring for the low frequencies. I should note you should only expect identical frequencies with identical belt lengths, carriage/gantry position, etc.

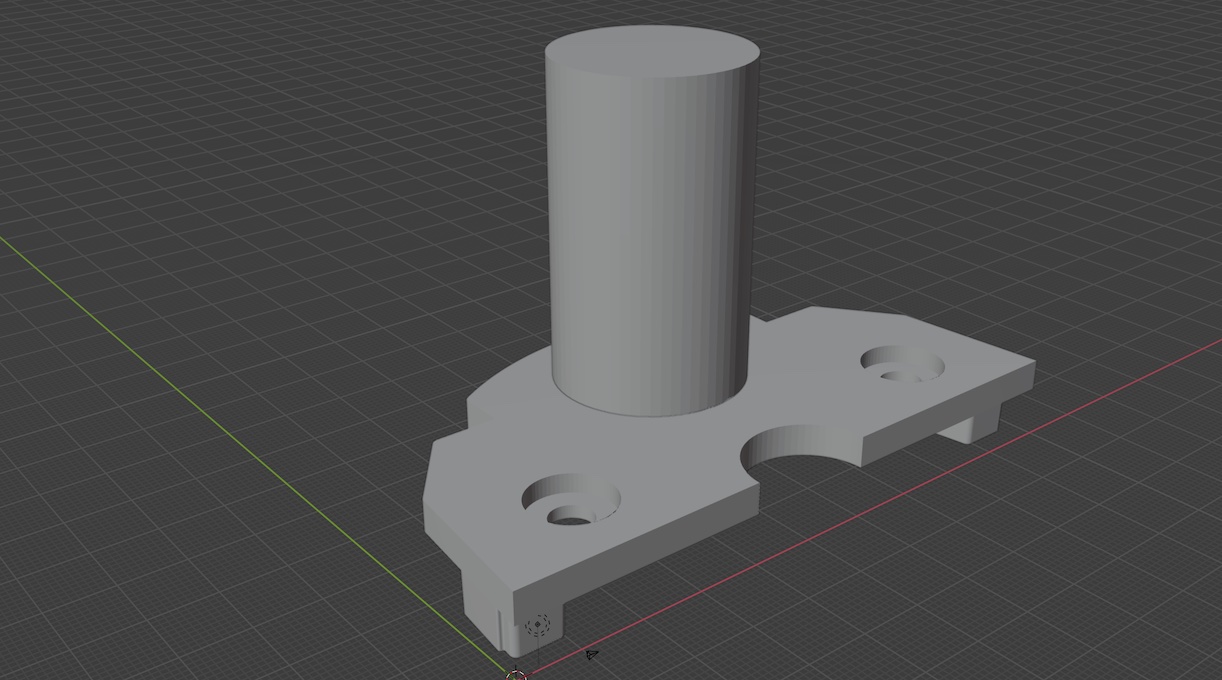

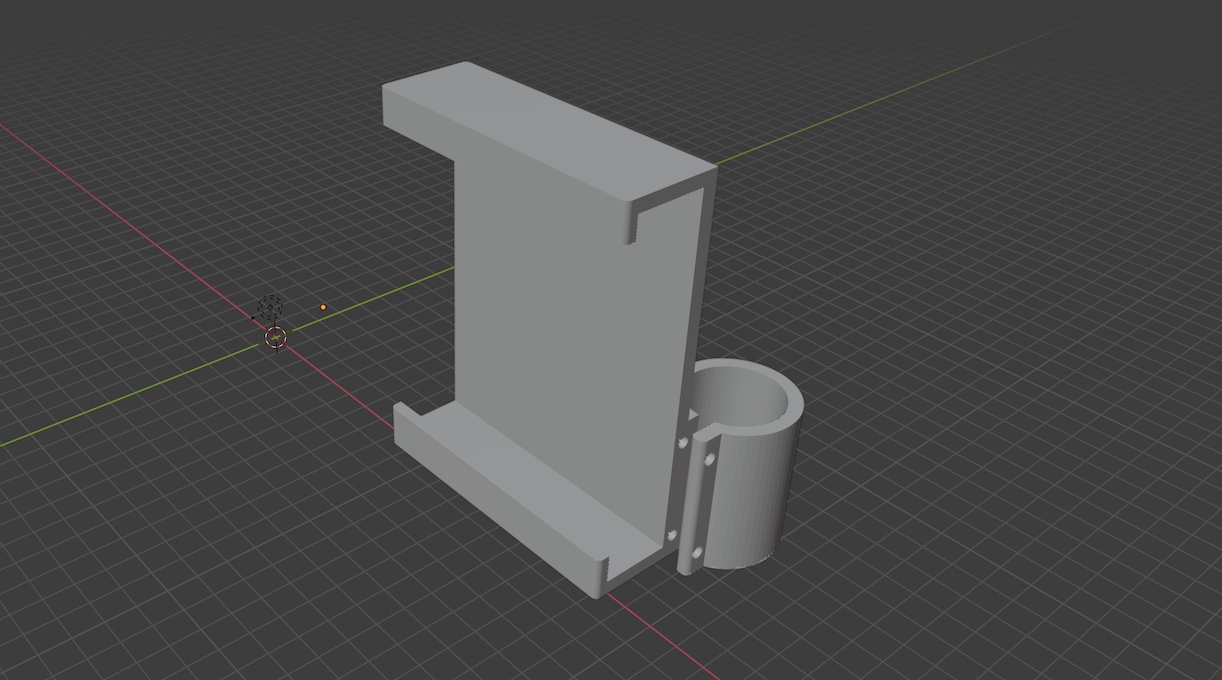

I wasn't a big fan of the detached Speeder Pad stand, so I made a mount for it. The clamp uses two M4 screws and it allows for different horizontal angles.